Thicker is better. What makes our Engineered Wood Floors better than most?

Posted: February 7, 20226mm Wear Layer Engineered Wood Flooring: Thicker is Better

Click this link for more information on our Engineered Rustic White Oak and our Engineered Rustic Hickory flooring.

Click this link to contact us and receive a delivered price to your project.

To understand why our thick 6mm engineered wood flooring stands out so much, let’s first off discuss what engineered flooring consists of. Engineered floors are constructed with an inner plywood core which is typically made from birch. Then a layer, called the “wear layer” is made from a more decorative wood species that is then fused on top of the plywood core. The 6mm wear layer is what you will see once our flooring is installed. Not only is our wear layer thicker, but it is also cut in a technique called “live sawn“. Live-sawn boards provide added stability and are less likely to warp and twist over time.

To understand why our thick 6mm engineered wood flooring stands out so much, let’s first off discuss what engineered flooring consists of. Engineered floors are constructed with an inner plywood core which is typically made from birch. Then a layer, called the “wear layer” is made from a more decorative wood species that is then fused on top of the plywood core. The 6mm wear layer is what you will see once our flooring is installed. Not only is our wear layer thicker, but it is also cut in a technique called “live sawn“. Live-sawn boards provide added stability and are less likely to warp and twist over time.

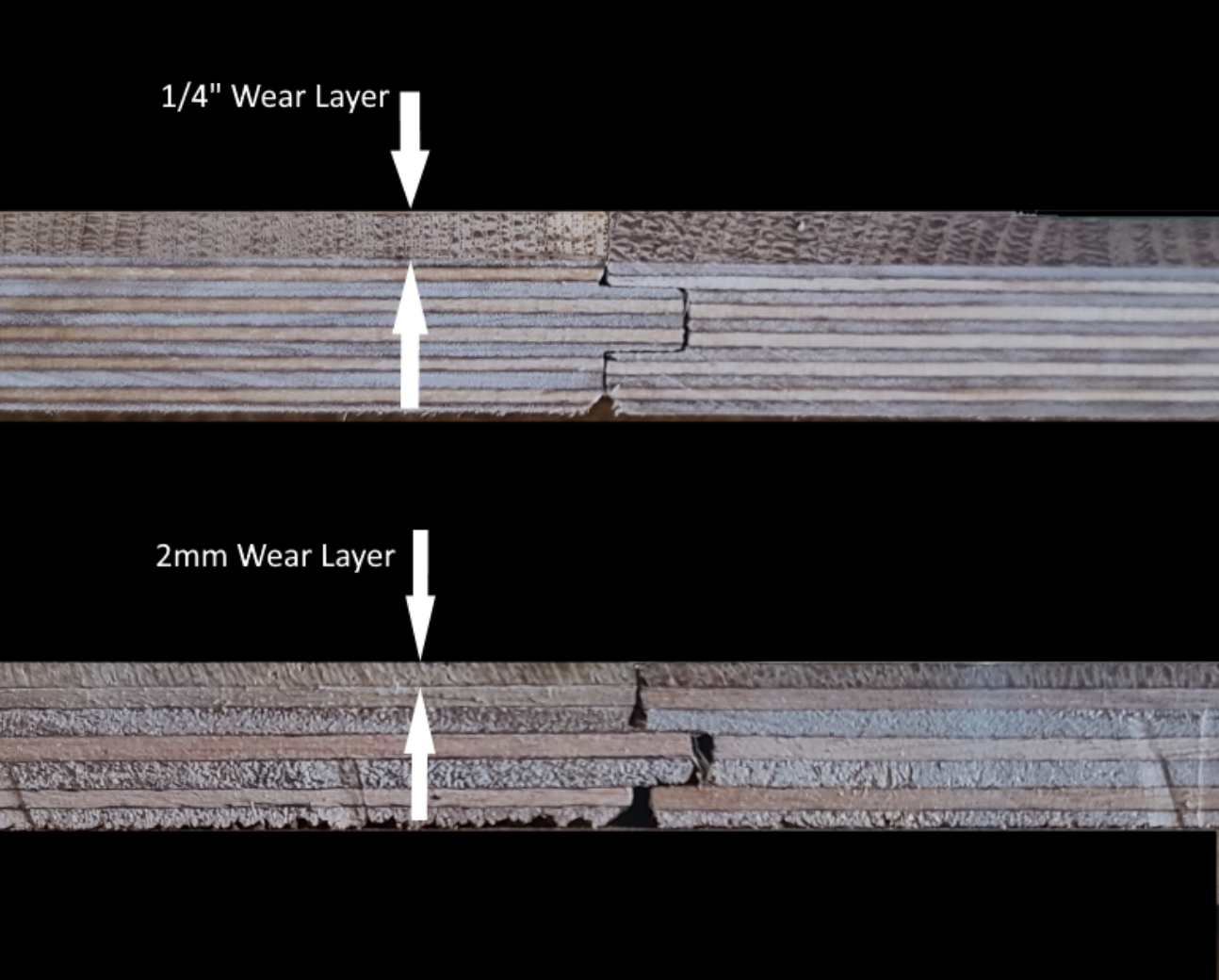

Our two thick engineered wood flooring options consist of Rustic White Oak and Rustic Hickory floors. Our rustic White Oak is available in two colors, Natural and Fumed. What makes these engineered flooring options so special? It’s the thickness of our wear layer. Most engineered floors have a fairly thin wear layer, typically 1-2 millimeters. The wear layer on our engineered flooring is ¼” thick, or approximately 6mm. This is a huge benefit, basically, the thicker the wear layer, the more durable the floor will be. Our thick engineered flooring can be refinished as many times as a solid wood floor. For example, an engineered floor with a 1mm wear layer cannot be sanded and refinished at all. It can only be recoated. A wear layer of 2mm could only be sanded and finished 1-2 times. A wear layer of 3mm could possibly be sanded and refinished up to 2-3 times and a 4mm wear layer up to 4-5 times. In comparison, our ¼” wear layer is similar to 6mm wear layer engineered flooring, which means sanding and refinishing will likely outlast our lifetime. It is said that the average homeowner has their hardwood floors sanded and refinished every 8-12 years.

For those of you who are visual, let’s compare.

In short, there are 3 major benefits to our thick engineered wood flooring because of its approximate 6mm wear layer.

- Lifespan – the floor lasts longer and can be sanded and finished multiple times

- Cost – you can sand and finish a thicker wear layer multiple times instead of having to replace a floor with a thinner wear layer once it wears through.

- Durability – a thicker wear layer ultimately can take on more of the wear and tear of everyday traffic

In addition to our thick wear layer, our engineered flooring comes prefinished with a water-based UV-cured Aluminum Oxide finish coat. This is arguably the most durable hardwood floor coating currently available on the market.

Full Specs:

- MINIMUM ORDER – 200 sq. ft.

- SURFACES – Floors or walls

- SPECIES – Rustic White Oak

- GRADE QUALITY – Epoxy-filled voids, graded to 99% usable

- HARDNESS – 1360 Janka Rating

- MOISTURE CONTENT – Cured & kiln dried to 6-8% moisture content

- THICKNESS – 3/4″

- WIDTHS – 8″ face coverage

- LENGTH – Random up to 8′

- GRAIN – Mixed

- PROFILE – Micro bevel edges, relief kerfs, clinch line, T&G, and end-matched (T&G on the ends)

- FINISH – No VOC UV-cured Aluminum Oxide clear matte finish

- PACKAGING – 21 square foot boxes

- DISTRIBUTION – Factory direct shipping anywhere in the U.S.

- INSTALLATION – Nail Down, Glue Down, Glue & Nail

- DISCLAIMER – This is a natural wood product. Color, texture, and grain will vary from board to board.

Our knowledgeable and educated staff is here to answer any additional questions you may have. Please call us today for a free quote: Ph# 406.642.7120 or click here to submit an inquiry online. We look forward to working with you on your next project!