How to Choose Engineered Hardwood Flooring

Posted: May 15, 2023Updated 6/27/2025

Author – Ryan Palma Owner/CEO Sustainable Lumber Co.

Click on this link for more information, photo’s, and pricing on our wide selection of hardwood flooring, or to contact us for a pricing quote.

How to Choose Engineered Hardwood Flooring

When it comes to choosing engineered hardwood flooring, you need to know that they are not all created equal. One of the most important factors to consider is the thickness of the wear layer. The wear layer is the topmost layer of the flooring that provides durability and protection. It can have a significant impact on the longevity and performance of the flooring. We’re going to cover why a thick wear layer like 6mm is rare and superior and why it’s worth investing in a high-quality wood floor like our Rustic Hickory or our Rustic White Oak engineered hardwood flooring.

What is an engineered hardwood wear layer?

Why is a thick wear layer superior when choosing engineered hardwood flooring?

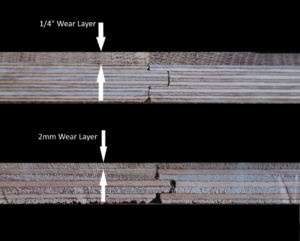

- Durability: A thick wear layer provides greater durability and resistance to scratches, scuffs, and other types of damage. This means that the flooring is less likely to show signs of wear and tear over time and will last longer than flooring with a thin wear layer.

- Resilience: A thicker wear layer also provides greater resilience to heavy foot traffic, furniture, and other types of impact. This means that the flooring is less likely to dent or deform under pressure, and it will maintain its appearance and structural integrity over time.

- Refinishing: Another advantage of a thick wear layer is that it can be refinished multiple times, allowing you to restore the appearance of the floor and extend its lifespan. For example, an engineered floor with a 6mm thick wear layer can be refinished as many times as a solid wood floor. With a thinner wear layer, there is a risk of sanding down the wear layer completely and revealing the plywood underneath, which can damage the flooring beyond repair. (Learn more about engineered vs. solid wood)

Why is a thick wear layer so rare?

In addition, a thicker wear layer requires more high-quality materials, which can increase the cost of production. This means that flooring with a thick wear layer is generally more expensive than flooring with a thinner wear layer.

However, the benefits of choosing and investing in a high-quality engineered hardwood floor with a thick wear layer can far outweigh the initial cost. Not only will the floor last longer and perform better, but it can also add value to your home and improve the overall aesthetic of your space.

Tips for choosing the right engineered hardwood floor.

- Look for flooring with a thick wear layer: As we’ve discussed, a thick wear layer provides greater durability and longevity, so it’s worth investing in flooring with a wear layer of at least 4mm thick.

- Choose a reputable manufacturer: Look for flooring from a manufacturer with a proven track record of quality and reliability. This can help ensure that you’re getting a high-quality product that will last. Don’t blindly trust the salesperson at your local flooring store, more often than not they are on commission and will tell you whatever you want to hear, do your own research.

- Consider the installation process: Make sure that the flooring is easy to install and that you have access to the tools and resources you need to complete the installation process. Be sure to follow the manufacturer’s recommended installation guidelines.

Our knowledgeable and educated staff is here to answer any additional questions you may have. Please call us today for a free quote: Ph# 406.642.7120 or click here to submit an inquiry online. We look forward to working with you on your next project!