Build with wood to reduce carbon dioxide emissions

Posted: October 8, 2018Source: Oregon Forests Resources Institute by Timm Locke Director of Forest Products

Why wood is better

There are a number of reasons building with wood instead of other materials can help reduce CO2 emissions, as Oliver points out. For one, trees absorb carbon dioxide and release oxygen as they grow. Carbon (the “C” in CO2) is stored in the wood of the tree. That carbon stays in the wood until the wood decomposes, at which time it re-binds with oxygen (the “O2” in CO2) and becomes carbon dioxide again.

As a result, about half the dry weight of wood is carbon that once was CO2. That’s true of all things wood, including wood pencils, wood flooring, 2x4s and mass timber products such as cross-laminated timber (CLT).

Storing carbon long-term

As a building material, wood typically has a long, useful life as it stores carbon that would otherwise be released into the air as CO2 – in some cases, as long as 100 years or more. And when a building reaches the end of its usefulness, it can be deconstructed and the wood products reused rather than being landfilled.

For the sake of easy math, let’s assume a portion of forest is harvested and the trees are converted to wood products at age 50. In doing so, we’ve removed carbon from the forest, released some CO2 in the process (but not nearly as much as we’ve removed and turned into wood products), and stored that carbon in buildings and other uses for the wood. Then we plant seedlings to replace the harvested trees, and the carbon sequestration process begins anew in the forest.

Fifty years later, we still have the vast majority of the previously stored carbon in the buildings we built half a century ago, and the new trees are ready to be harvested and milled into wood products. Now we have two times the carbon stored in buildings and wood products, and a new forest is planted and beginning the sequestration process again. As long as the buildings last longer than the age of the trees that are harvested, there is a net-positive carbon effect.

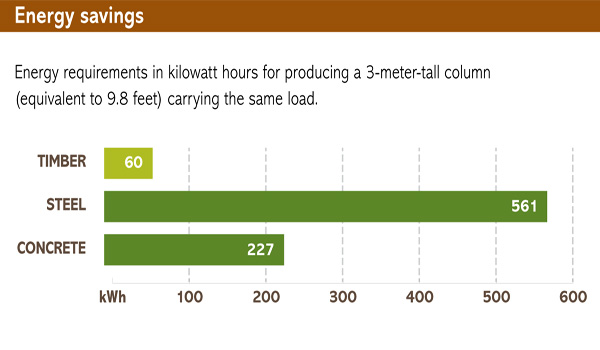

Wood takes less energy to produce

Other building materials, primarily concrete and steel, don’t store any carbon, and they require far more energy consumption than is required to produce wood products. This results in increased greenhouse gas emissions. In fact, compared to building with wood, it takes more than nine times as much energy to produce steel, and nearly four times as much energy to produce concrete.

Making concrete, for instance, involves heating limestone to very high temperatures, resulting in a chemical process called “calcination,” which amounts to about 50 percent of concrete’s CO2 emissions. This helps explain why concrete, the second most consumed substance on earth, accounts for around 5 percent of total global CO2 emissions.

Carbon12, an eight-story condo tower in Portland that is currently the tallest wood building in the U.S., has 577 metric tons of CO2 equivalent stored in the wood it uses, and an additional 223 metric tons of emissions were avoided by choosing wood instead of steel and concrete. The First Tech Federal Credit Union office in Hillsboro, which at 156,000 square feet is currently the largest CLT building in the U.S., has 4,192 metric tons of CO2 equivalent stored in the wood, and 1,622 tons of CO2 emissions were avoided. That’s just two relatively small buildings. Imagine what would be possible if all our buildings were wood.

A renewable resource

But could they be? Besides its positive carbon story, wood is also the only renewable resource we have with which to build. We can grow what we need, and when we use it we can replace what we used. You might be surprised at just how productive our forests are. Timberland in Oregon (defined as forestland that is capable of growing timber and potentially available for harvest, excluding parks, wilderness areas or reserves) grows enough wood to replace the amount used in the First Tech project in 46 minutes, and enough wood to replace the amount used in Carbon12 in just 6 minutes.

That means that without depleting natural resources, we can be constructing more buildings with wood instead of steel and concrete, as Oliver suggested at the Oregon Coastal Caucus, and help combat climate change in the process.

Timm Locke

Director of Forest Products